ZJ Composites fiberglass grating for sale

Links

- The importance of cheap barium sulfate superfine factory cannot be overstated. Firstly, it provides manufacturers with access to high-quality raw materials at competitive prices, which helps reduce production costs and increase profitability. Secondly, the availability of cheap barium sulfate enables companies to innovate and develop new products that were previously unaffordable. Finally, the presence of these factories stimulates economic growth by creating jobs and attracting investment in the region.

-

The FDA's Code of Federal Regulations allows for the legal, regulated use of titanium dioxide in food products, under some restrictions.

- In the food and pharmaceutical industries, titanium dioxide powder is used as a white pigment in a variety of products, including candies, toothpaste, and medications. It is important for suppliers to provide titanium dioxide powder that is safe for use in food and pharmaceutical applications and complies with strict regulatory requirements.

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials

These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials These minerals can improve the tear strength, abrasion resistance, and flexibility of rubber materials talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.

talc titanium dioxide manufacturer. This is because talc provides reinforcement, while titanium dioxide enhances the cross-linking density of the rubber molecules, making them more resistant to deformation under stress.  By evaluating suppliers using this framework, businesses can identify those that meet their requirements and are likely to provide long-term value By evaluating suppliers using this framework, businesses can identify those that meet their requirements and are likely to provide long-term value

By evaluating suppliers using this framework, businesses can identify those that meet their requirements and are likely to provide long-term value By evaluating suppliers using this framework, businesses can identify those that meet their requirements and are likely to provide long-term value ba311 supplier.

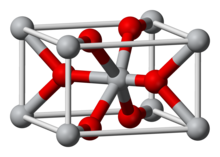

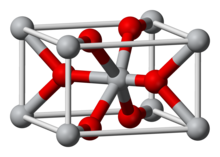

ba311 supplier. ZnSO4+BaS→ZnS+BaSO4

Restraint

The chemical is also found in common household and industrial products such as paints, coatings, adhesives, paper, plastics and rubber, printing inks, coated fabrics and textiles, as well as ceramics.

On the other hand, some of the top manufacturers of titanium dioxide include Chemours, Tronox, and Kronos

. These companies have advanced chemical processing facilities that can produce high-quality titanium dioxide for various applications.Titanium dioxide is a mineral that’s used as a white coloring in a variety of products, including sunscreens, cosmetics, paints, and plastics. The pigment grade is also known as titanium white, pigment white 6, or CI 77891; it's the whitest and brightest of all known pigments.

In 2019, EFSA published a statement on the review of the risk related to the exposure to food additive titanium dioxide (E171) performed by the French Agency for Food, Environment and Occupational Health Safety (ANSES). In its statement, EFSA highlighted that the ANSES opinion reiterated the uncertainties and data gaps previously identified by EFSA and did not present findings that invalidated the Authority’s previous conclusions on the safety of titanium dioxide.

When it comes to sourcing titanium dioxide, it is essential to understand the various processes involved in its production. The two primary production methods are the sulfate process and the chloride process. The sulfate process tends to be more cost-effective in certain contexts, but it also generates a substantial amount of waste, putting pressure on manufacturers to invest in waste treatment technologies. On the other hand, the chloride process is known for its superior quality and lower environmental impact, albeit at a higher production cost.

Titanium dioxide manufacturer: Lomon

Hebei Caixin Material Technology Co., LTD., formerly established in 2005, is located in the core of Beijing-Tianjin-Hebei City cluster, close to Tianjin Port, the largest port in the north, with developed transportation and outstanding people. After the continuous efforts of Caiqing people, has accumulated assets for the company of nearly 200 million, nearly 1,000 employees, Caiqing technology has become the pigment titanium dioxide research and development, production, sales and import and export trade in one of the large company, we integrate industry resources, to provide personalized customized services for global customers. We adhere to the market-oriented, good faith as the principle, is committed to open up a diversified international market, for the world customers to provide quality products, efficient service, is our unremitting pursuit. We sincerely invite customers from all over the world to visit our company.